Modular Cooking Systems for Food Industry

CelsiusFOOD has developed completely unique cooking solutions made up of modular sections. Our mission is to offer the food industry the most suitable and flexible cooking system for higher performances and better product quality . To do this, we combine different heat transfer methods in one system for seamless browning, roasting, heating and cooling. We use a modular cooking technology.

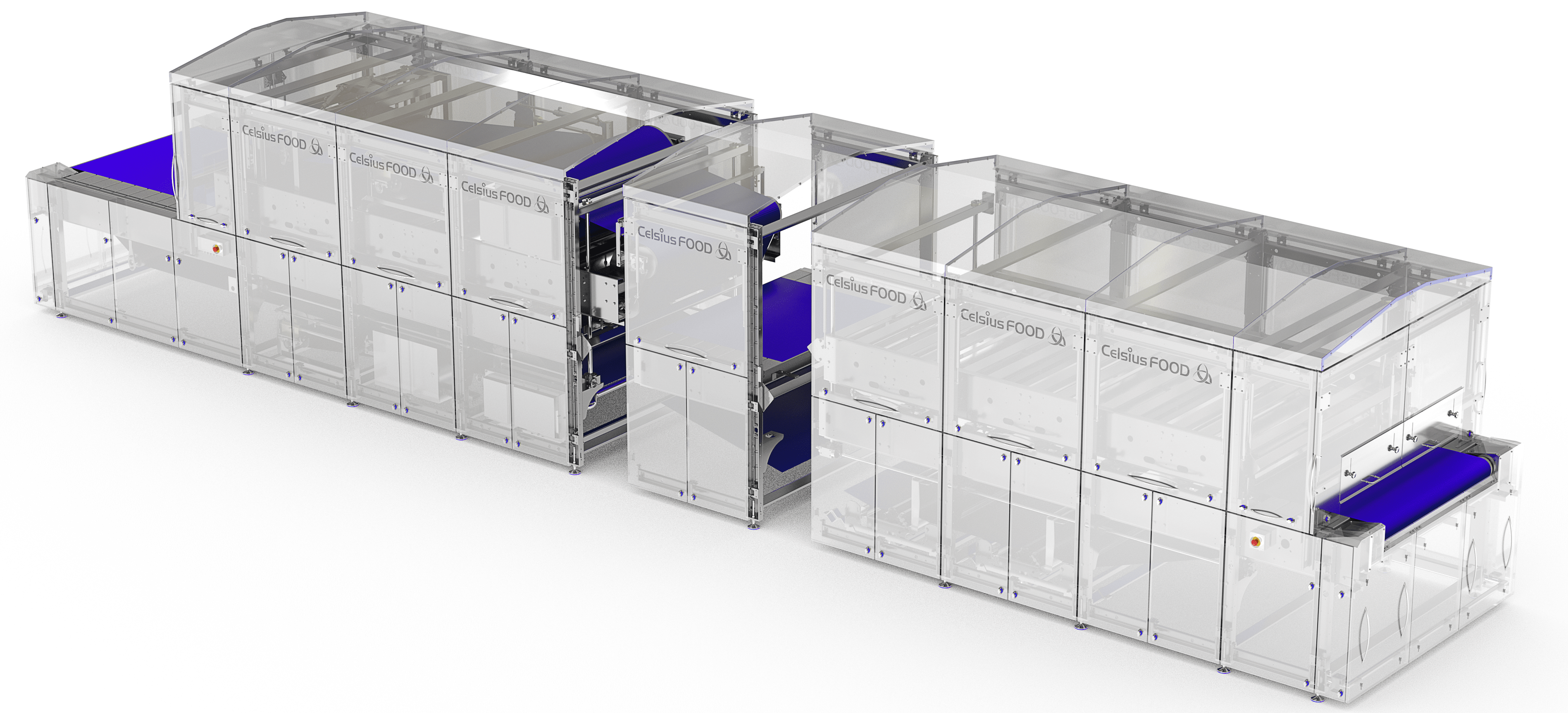

Industrial cooking system: the excellence of modularity through United Thermal Technologies

At CelsiusFOOD, we call it the UTT system. It is a unique and innovative way to design the perfect cooking solution for manufacturers. Our modular systems make 2-stage cooking possible: brown the product briefly using intense heat and then cook it through more gently. We can also add a third stage for pre-cooling.

CelsiusFOOD’s new generation of cooking systems for food industry are made up of modules which all have the same framework. Therefore, each module can be assembled one after another. In addition, each module can be equipped with a different thermal technique for searing, broiling, baking and even cooling. We can then build your ideal linear oven like a LEGO construction. These cooking systems for food industry can be designed with or without product transfer between different sections and techniques. More modules generate longer systems for greater throughput.

Food cooking lines: our definition of flexibility

Adding more modules with the same thermal technique increases your production capacity. Our modular cooking system means that you can extend your tunnel oven in the future. No need to overinvest, you can buy a system for the capacity you need now. Thanks to the modular concept of our linear ovens, you can invest today in a cooking system to meet your current need and 2, 3 or 5 years later, double your capacity by adding an extra cooking module.

Adding modules with a different thermal technique changes the process configuration. In fact, sections of modules can also be linked to form a linear system which uses more than one thermal technique. Thus, from the finished product you want to obtain, we are able to combine different cooking and cooling techniques to create your perfect food processing system. This modular concept also makes it possible to process many different products with only one thermal linear system.

OUR SOLUTIONS FIT YOUR PRODUCTS, NOT VICE VERSA. THIS IS OUR DEFINITION OF FLEXIBILITY.

Our cooking technologies provide homemade quality and style

Each cooking module can cook the product by conduction and/or convection. The combination of different methods of heat transfer is our answer to processing not only products that look homemade but also products which taste homemade.

The unique and innovative use of PTFE Teflon conveyors allows powerful direct conduction cooking without leaving industrial belt marks on your food products. The way of cooking we offer provides the food industry with a homemade appearance and quality by combining different thermal technology in a single food processing line.

Non-stick conveyor belt for healthier food

The conveyors are covered with Teflon. Thanks to the non-stick property of Teflon, you can cook most products without adding extra fat . No need to add any oil, your product will not stick to the belts and the quality of your product will be valued by your customers. This healthier approach to the industrial cooking process opens up wider possibilities especially for food products such as vegetarian food or fish.

Our cooking systems for food industry: an economical and sustainable solution

Stainless steel heating plate

Our cooking systems are equipped with heating plates made of stainless steel for thermal fluid or electrical heating. This choice of material makes your heating plates more durable with no risk of corrosion despite repetitive cleaning and brushing processes.

Exchangeable heating coils

Electrical heating plates are fitted with exchangeable heating coils so that in the event that a heating plate malfunctions, only the defective element needs to be replaced instead of the whole heating plate. You replace only what is necessary. You pay only what is necessary.

Autonomous maintenance

Our linear cooking systems for food industry have been crafted and designed to be easy to use and maintain. We provide our customers with training on how to maintain their food equipment independently. All the components conform to ISO standards and can be sourced in any country.

Easy-to-clean system

The conveyor belts are continuously steam cleaned. They are also equipped with an auto-lifting system to facilitate cleaning of the equipment. In this way, the cleaning staff do not need to have the strength to hold them up but have free access to wash the heating plates.

Finding the best thermal configuration of a UTT system that cooks (and cools) your products with optimal results requires trials and expertise. Contact a CelsiusFOOD application engineer to help you finding the best cooking systems for food industry.